Unlock Profit with Inventory Optimization

Managing inventory is a delicate balancing act for any business, regardless of size or industry. Too much stock ties up valuable capital, incurs high storage costs, and risks obsolescence, while too little stock can lead to missed sales, dissatisfied customers, and production delays. This inherent tension highlights the critical need for inventory optimization, a strategic approach that aims to find the ideal balance between meeting customer demand and minimizing inventory-related costs. It's not just about counting items; it's about smart, data-driven decision-making that impacts every facet of a business, from cash flow to customer loyalty.

At its core, inventory optimization moves beyond traditional inventory management, which often relies on historical averages or simple reorder points. Instead, it employs sophisticated analytical techniques, forecasting models, and technology to predict demand more accurately, understand supply chain variability, and set optimal stock levels for each product SKU across various locations. This proactive methodology transforms inventory from a necessary evil into a strategic asset.

The benefits of mastering this balance extend far beyond mere cost savings. Businesses that effectively optimize their inventory can experience significant improvements in their financial health, operational efficiency, and competitive standing. It enables a more agile response to market changes, reduces waste, and frees up capital that can be reinvested into growth initiatives.

In today's fast-paced global economy, where supply chain disruptions are increasingly common and customer expectations are higher than ever, the ability to optimize inventory is no longer a luxury but a fundamental requirement for sustained profitability and survival. This article will delve into what inventory optimization entails, its profound benefits, the strategies and technologies that power it, and the best practices for implementing it successfully within your organization.

What is Inventory Optimization?

Inventory optimization is a comprehensive approach to managing a company's stock levels with the goal of maximizing profitability by balancing inventory costs with customer service levels. It involves using advanced analytical techniques and software to determine the optimal quantity and location of inventory at each stage of the supply chain, considering factors like demand variability, lead times, supply reliability, and cost parameters. Unlike basic inventory management, which might focus simply on tracking stock, optimization delves into predictive analytics and strategic planning to ensure the right product is in the right place at the right time, at the lowest possible cost.

This process moves beyond a reactive stance, where companies order more stock only when levels run low, to a proactive, data-driven methodology. It considers the entire supply chain network, analyzing interdependencies between different products, warehouses, and distribution centers. The core objective is to minimize the total cost of inventory, which includes holding costs, ordering costs, and the cost of stockouts, while simultaneously achieving predefined service level targets. This intricate balance requires a deep understanding of market dynamics, internal operations, and the financial implications of every inventory decision.

The Pervasive Benefits of Effective Inventory Optimization

Implementing effective inventory optimization yields a cascade of benefits that directly impact a company's bottom line and operational health. These advantages reinforce its position as a strategic imperative rather than just an operational task.

Reduced Carrying Costs

One of the most immediate and tangible benefits is the significant reduction in carrying costs. These costs encompass warehousing expenses (rent, utilities, labor), insurance, security, obsolescence, damage, and depreciation. By holding only the optimal amount of stock, businesses can free up warehouse space, reduce waste from expired or obsolete goods, and lower insurance premiums, directly improving profitability.

Improved Cash Flow and Working Capital

Excess inventory acts as trapped capital that could otherwise be used for investments, debt reduction, or other business needs. By optimizing inventory levels, companies can unlock this working capital, improving their cash flow and financial liquidity. This increased financial flexibility allows for greater agility and resilience, especially during economic downturns or periods of rapid growth.

Enhanced Customer Satisfaction and Service Levels

While cost reduction is a primary driver, inventory optimization also directly improves customer satisfaction. By minimizing stockouts and ensuring product availability, businesses can fulfill orders promptly and reliably. This leads to higher customer retention rates, positive brand perception, and a competitive edge in the marketplace where product availability is often a key differentiator.

Increased Operational Efficiency

Optimized inventory leads to smoother operations throughout the supply chain. Reduced stockouts mean fewer rushed orders and less reactive decision-making. Better inventory visibility and accuracy streamline warehouse operations, picking processes, and shipping, leading to greater productivity and reduced labor costs. It allows for a more predictable and stable operational environment.

Better Decision-Making

A robust inventory optimization strategy relies heavily on data and analytics. This process inherently forces companies to collect, clean, and analyze relevant data, providing invaluable insights into demand patterns, supplier performance, and internal efficiencies. These insights empower management to make more informed strategic decisions across various business functions, not just inventory.

Mitigation of Supply Chain Risks

In an increasingly volatile global landscape, inventory optimization helps businesses build resilience against supply chain disruptions, whether they are due to geopolitical events, natural disasters, or supplier issues. By understanding optimal safety stock levels and diversifying sourcing, companies can better absorb shocks and maintain continuity of supply to their customers.

Key Strategies and Techniques for Inventory Optimization

Achieving true inventory optimization requires a multi-faceted approach, integrating various strategies and techniques across the supply chain.

Demand Forecasting Excellence

Accurate demand forecasting is the bedrock of effective inventory optimization. It involves predicting future customer demand based on historical data, market trends, seasonality, promotional activities, and external factors like economic indicators or competitor actions. Advanced forecasting models, leveraging statistical methods (e.g., moving averages, exponential smoothing, ARIMA) and increasingly machine learning, can significantly improve predictive accuracy, allowing businesses to align inventory levels more closely with anticipated sales.

Lead Time Management

Understanding and actively managing lead times – the time between placing an order and receiving the goods – is crucial. Shorter, more reliable lead times allow for lower safety stock levels. This involves fostering strong relationships with suppliers, negotiating for faster delivery, and identifying potential bottlenecks in the procurement and transportation processes.

Safety Stock Calculation

Safety stock is the extra inventory held to guard against uncertainties in demand or supply. Calculating the optimal safety stock involves balancing the risk of stockouts against the cost of holding excess inventory. It considers demand variability, lead time variability, and the desired customer service level. Sophisticated models help determine dynamic safety stock levels that adjust to changing conditions.

Reorder Point and Quantity Optimization

The reorder point (ROP) is the inventory level at which a new order should be placed. The reorder quantity is how much should be ordered. Techniques like the Economic Order Quantity (EOQ) model help determine the optimal order quantity that minimizes total ordering and holding costs. Modern optimization goes beyond EOQ, integrating demand variability and service level targets to set more precise reorder points and quantities.

ABC Analysis

ABC analysis categorizes inventory items based on their value or importance. "A" items are high-value, fast-moving items that require close monitoring and frequent review. "B" items are moderate in value and turnover, while "C" items are low-value, slow-moving items that can be managed with less stringent controls. This Pareto principle application ensures resources are allocated to managing the most critical inventory components.

Just-In-Time (JIT) and Lean Principles

JIT aims to minimize inventory by receiving goods only as they are needed for production or sale. While challenging to implement perfectly due to supply chain complexities, incorporating lean principles – focusing on waste reduction and efficiency throughout the supply chain – can significantly reduce inventory holding costs and improve flow.

Vendor-Managed Inventory (VMI)

In VMI, the supplier takes responsibility for managing and replenishing the buyer's inventory. This collaborative approach can lead to lower inventory levels for the buyer, reduced stockouts, and improved supply chain efficiency through better communication and shared forecasting.

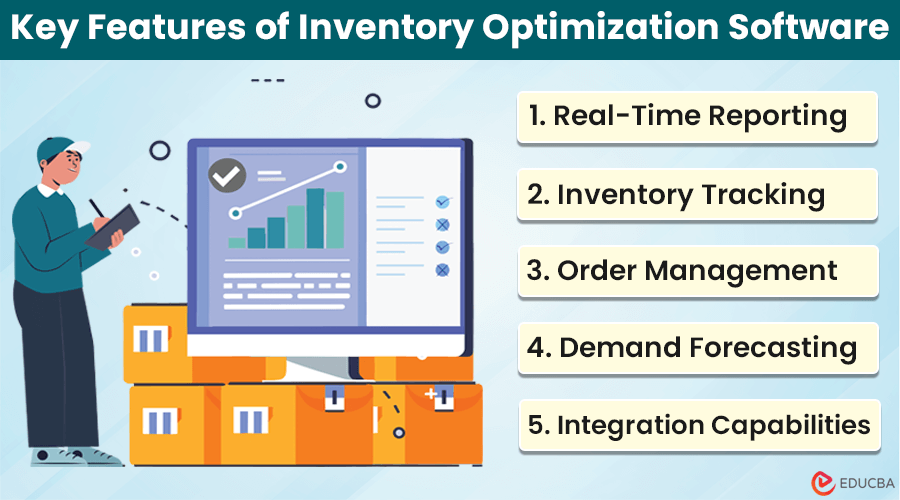

Leveraging Technology for Advanced Inventory Optimization

The complexity of modern supply chains and the sheer volume of data involved make technology an indispensable tool for achieving sophisticated inventory optimization.

Inventory Management Systems (IMS) and ERPs

At a foundational level, robust Inventory Management Systems (IMS) or Enterprise Resource Planning (ERP) systems are essential. These systems provide real-time visibility into inventory levels across multiple locations, track movements, manage orders, and facilitate basic reporting. They serve as the central repository for inventory data, enabling more advanced analysis.

Advanced Planning & Scheduling (APS) Software

APS software goes beyond basic ERP functionality by incorporating sophisticated algorithms for demand forecasting, inventory planning, and production scheduling. These systems can model complex supply chain scenarios, optimize inventory policies, and generate recommendations for ordering, production, and distribution to meet service level targets at minimum cost.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are revolutionizing inventory optimization by providing unparalleled predictive capabilities. ML algorithms can analyze vast datasets to identify subtle patterns and correlations that human analysts might miss. They can learn from historical data to improve forecasting accuracy, predict potential disruptions, dynamically adjust safety stock levels based on real-time conditions, and even optimize pricing strategies to manage inventory.

Internet of Things (IoT) for Real-time Visibility

IoT devices, such as RFID tags and smart sensors, can provide real-time, granular data on inventory location, movement, and even condition (e.g., temperature for perishables). This enhanced visibility minimizes manual errors, reduces shrink, and enables more accurate inventory counts, feeding critical data into optimization algorithms for more precise decision-making.

Overcoming Challenges in Inventory Optimization

While the benefits of inventory optimization are clear, implementing and sustaining it can present several challenges.

Data Accuracy and Availability: Poor data quality, inconsistent data formats, or a lack of historical data can cripple even the most advanced optimization efforts. Clean, accurate, and comprehensive data is paramount.

Volatility in Demand and Supply: Unpredictable fluctuations in customer demand or unexpected disruptions in the supply chain (e.g., supplier delays, shipping issues) make forecasting and planning difficult. Building resilience and flexibility is key.

Lack of Integrated Systems: Disparate systems that don't communicate with each other create data silos and hinder a holistic view of inventory. Integration of ERP, IMS, and planning software is crucial.

Resistance to Change: Implementing new processes and technologies often faces resistance from employees accustomed to traditional methods. Effective change management, training, and demonstrating the benefits are vital.

Balancing Competing Objectives: Inventory optimization often involves trade-offs, such as balancing the desire for low inventory costs with the need to maintain high customer service levels. Finding the optimal balance requires careful consideration of business priorities.

Measuring Success: Key Performance Indicators (KPIs) in Inventory Optimization

To ensure ongoing improvement and validate the effectiveness of inventory optimization efforts, businesses must track relevant Key Performance Indicators (KPIs).

- Inventory Turnover Ratio: Measures how many times inventory is sold and replaced over a period. A higher ratio generally indicates efficient inventory management.

- Days Sales of Inventory (DSI): Indicates the average number of days it takes for a company to turn its inventory into sales. A lower DSI is usually better.

- Stockout Rate: The percentage of orders or line items that cannot be fulfilled due to lack of inventory. A low stockout rate is a goal of optimization.

- Order Fill Rate: The percentage of orders completely fulfilled on the first shipment. Higher rates indicate better customer service.

- Inventory Accuracy: The discrepancy between physical inventory counts and system records. High accuracy is fundamental for effective optimization.

- Carrying Cost of Inventory: The total cost of holding inventory over a period, expressed as a percentage of inventory value. Lowering this percentage is a direct benefit of optimization.

Best Practices for Sustainable Inventory Optimization

Achieving and maintaining optimized inventory levels is an ongoing journey that requires continuous effort and strategic commitment.

Start with a Clear Strategy and Objectives: Define what success looks like. Are you aiming to reduce costs, improve service, or both? Clear objectives guide the entire optimization process.

Invest in Data Quality: Prioritize cleaning and maintaining accurate data. Garbage in, garbage out – quality data is the fuel for effective optimization. Implement processes for continuous data validation.

Foster Cross-Functional Collaboration: Inventory impacts sales, marketing, finance, and operations. Break down silos and encourage collaboration to ensure alignment on forecasts, promotions, and supply plans.

Embrace Technology: Leverage modern IMS, ERP, APS, AI, and ML tools. These technologies provide the analytical power and real-time visibility necessary for advanced optimization.

Regularly Review and Adapt: Market conditions, demand patterns, and supplier performance are constantly changing. Regularly review your inventory policies, forecasts, and KPIs, and be prepared to adapt your strategies accordingly.

Continuous Training and Development: Equip your team with the knowledge and skills needed to utilize optimization tools and interpret data effectively. A knowledgeable workforce is crucial for sustainable success.

Conclusion

Inventory optimization is far more than just a logistical exercise; it's a strategic imperative that underpins financial health, operational agility, and customer satisfaction in today's competitive landscape. By moving beyond traditional inventory management to embrace data-driven forecasting, sophisticated analytical techniques, and advanced technologies, businesses can transform their inventory from a potential liability into a significant source of competitive advantage. The journey towards optimal inventory levels involves overcoming challenges like data quality issues and supply chain volatility, but the pervasive benefits—from reduced carrying costs and improved cash flow to enhanced customer service and resilient operations—make the investment unequivocally worthwhile. For any organization looking to unlock profitability and build a sustainable future, mastering the art and science of inventory optimization is not merely an option, but a fundamental requirement for success.